LABELLING SYSTEM SERIES 3

The unit is designed to accurately apply labels on PCB’s or on top of SERIES components. It uses a X-Y gantry to move the applicator head between the label printer and the placement position. The PCB is clamped in position and supported from the bottom by manual positioned magnetic support pins while one or more labels are applied at any desired position. The number of labels and their positions are easily programmed in WindowsTM based software.

STANDARD FEATURES

- Rigid machine structure with large access doors.

- Integrated 600 dpi printer.

- ZebraDesigner 2 user license.

- Slide-out mechanism (rear-side) for easy and fast label or ribbon replacement.

- Label rotation programmable in 1° step.

- Vacuum sensing of the label from pick-up to placement.

- CCD camera to read label before pick-up.

- Controlled by industrial PC.

- Conveyor width adjustment using hand crank.

- PCB side clamping.

- Active support base including 4 magnetic pins.

- Quick product change-over.

- Selectable by-pass operation.

- Uninterruptible power supply (UPS).

- Towerlight display for machine status.

- CE certified.

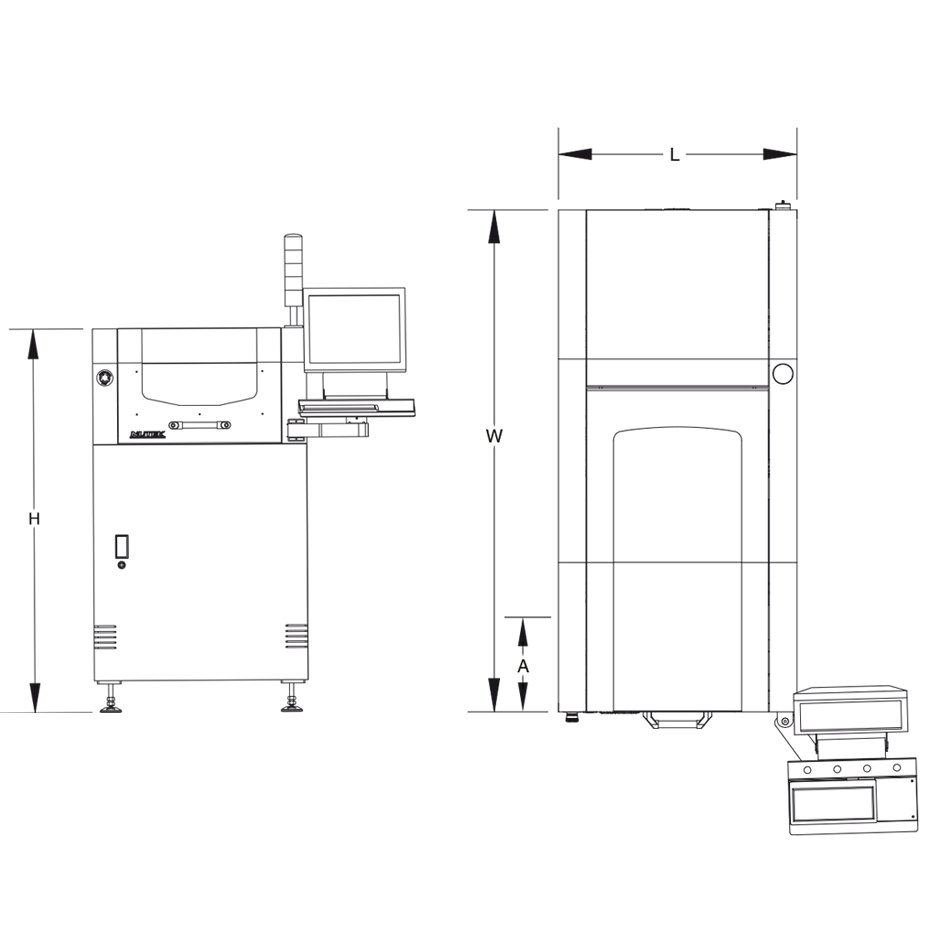

TECHNICAL DRAWING

OPTIONS

- Program controlled conveyor width adjustment

- Double sided labelling using integrated inverter

- Active PCB bottom support in combination with integrated inverter

- Database- and network connection

- PCB orientation check

- Other options available on request

SPECIFICATIONS

Printer type

Zebra ZT610 (600 dpi)

Minimum label size

6 x 6 mm

Label creation software

ZebraDesigner 2

Cycle time

2.5 sec. per label (6 x 6 mm)

Labelling area

460 x 460 mm

Conveyor type

3 mm ESD edge belt

Conveyor speed

24 m/min

System software

Windows

Network interface

Ethernet

Monitor

21” high-density flatscreen

PCB transfer height

950 mm ± 25 mm*

Component clearance

Top 30 mm, bottom 30 mm*

Machine interface

SMEMA*

Colour

RAL9002*

Power supply

230 VAC/50 Hz/1 Ph

Power consumption

700 VA max.

Air supply

6 bar

Air consumption

70 ltr/min max.

Noise level

Max. 65 dB

* or specify

MACHINE SIZES

BLCS3

Machine L x W x H (mm)

850 x 1680 x 1440

Weight (Kg)

750

Applicable PCB Length (mm)

80 - 508

Applicable PCB Width (mm)

65 - 460

PCB thickness (mm)

0.6 - 4

Fixed rail to front (A) (mm)

335

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.