LASER MARKING SYSTEM SERIES 3

The unit is designed to accurately mark PCB’s within a production line or SERIES can be used as a stand alone cell. A “flying laser” concept is used which means that the PCB is locked in the marking position while the CO2 laser is moved using servo controlled X-Y axis. The number of markings and their positions are easily programmed in WindowsTM based software. An optional integrated inverter is available for double- sided marking.

STANDARD FEATURES

-

CCD camera for readability check.

-

Three level camera lighting (brightness)

-

Large marking area.

-

Controlled by industrial PC.

-

Capability to mark text, barcodes, 2D codes and graphics.

-

Conveyor width adjustment using hand crank.

-

Rigid machine structure with large access doors.

-

PCB side clamping.

-

Mechanical PCB lift for constant focal point.

-

Quick product change-over.

-

Selectable by-pass operation.

-

Uninterruptible power supply (UPS).

-

Towerlight display for machine status.

-

CE certified.

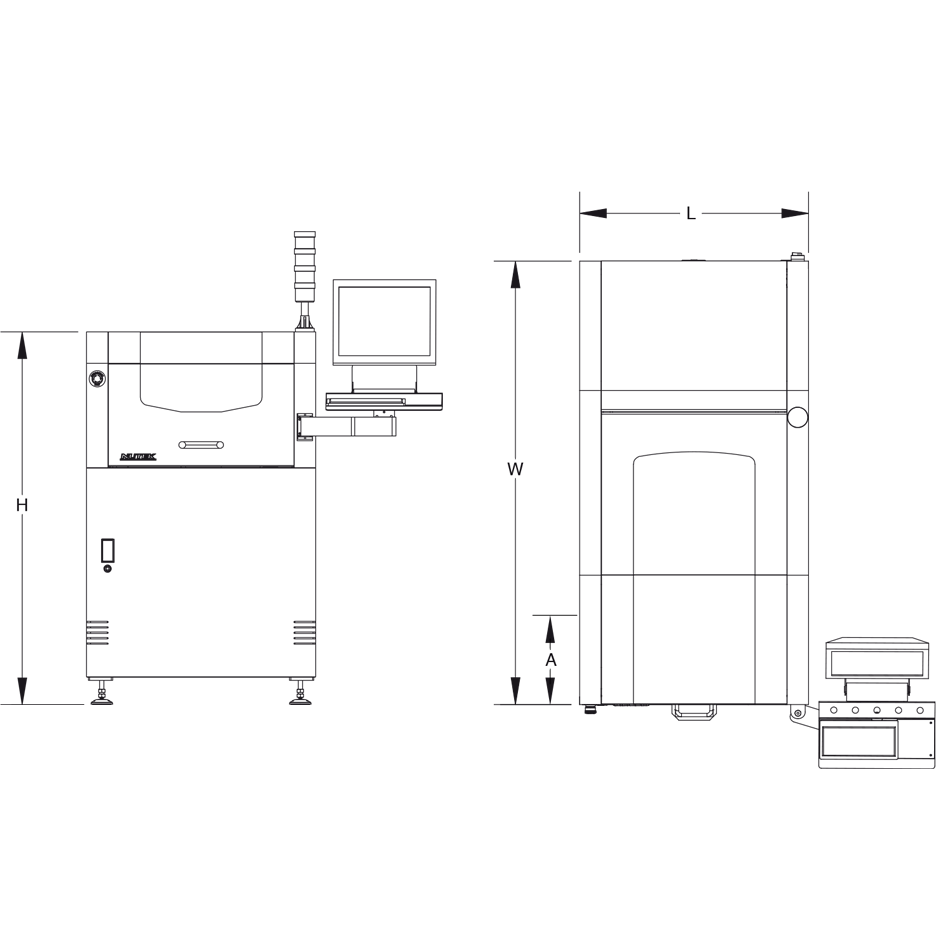

TECHNICAL DRAWING

OPTIONS

- Program controlled conveyor width adjustment

- PCB orientation check

- Fiducial recognition and position alignment

- Double-sided marking using integrated inverter

- Barcode scanner (Microscan MS4)

- Bad marking recognition

- Database- and network connection

- Fiber laser

- Fume extraction unit (external, 1000 VA max.)

- Label feeder module

- Other options available on request

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.