DUAL TRACK CONVEYOR TRAVERSER

The Dual Track Conveyor Traverser is placed between dual track machines having different fixed-to-fixed rail specifications. While a stationary conveyor passes PCB’s at the front track, a shuttle in the rear is moving between both up- and downstream rear tracks.

STANDARD FEATURES - DUAL TRACK CONVEYOR TRAVERSER

- Adjustable traversing distance (max. 1500 mm).

- Operation mode (2 in 2 out).

- Conveyor width adjustment using hand crank.

- Hinged top cover.

- Controlled by PLC.

- Frequency controlled traversing speed.

- CE certified.

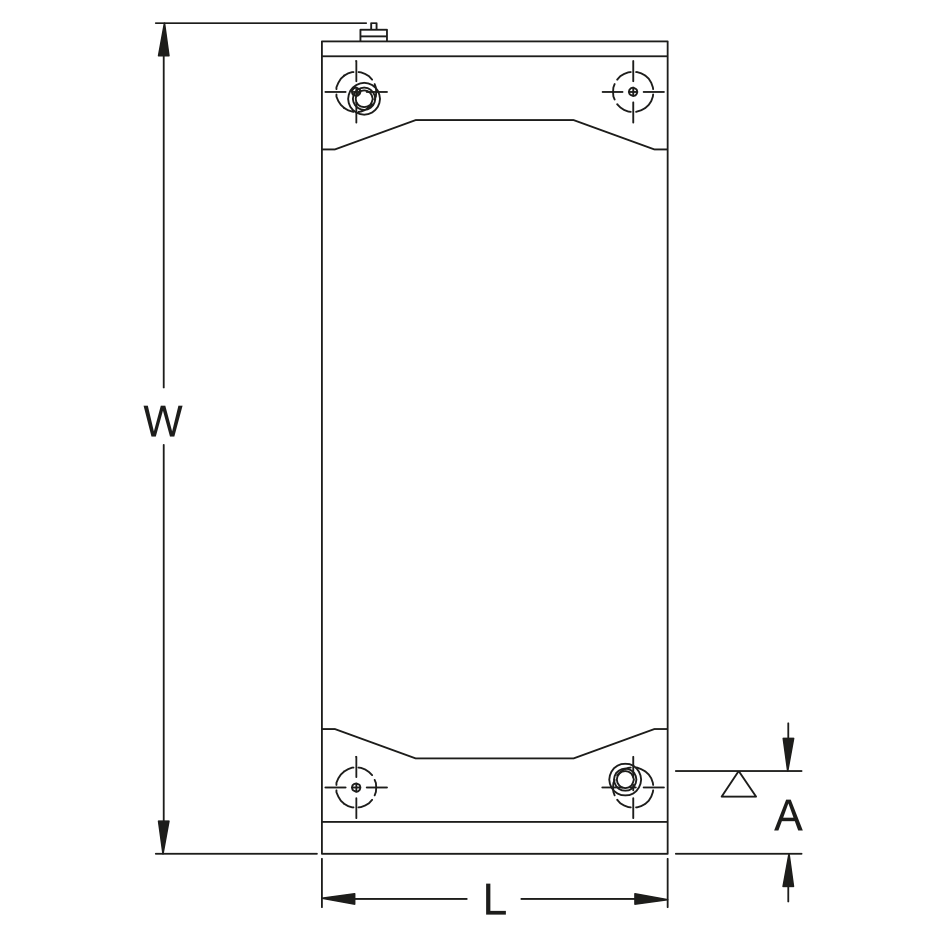

Technical drawing - DUAL TRACK CONVEYOR TRAVERSER

OPTIONS

- Customized traversing distance (4000 mm max.)

- Servo drive upgrade for shortened cycle time

- Electrical conveyor width adjustment.

- Automatic conveyor width adjustment

- Variable speed per segment

- Dual speed per segment

- Touchscreen display

- LED towerlight display for machine status

- Alarm buzzer.

- Other options available on request

SPECIFICATIONS

Transfer height

950 mm ± 25 mm*

Colour

RAL 9002*

Flow direction

Left to right*

Fixed rail

Front*

Machine interface

Dual lane SMEMA*

Conveyor concept

ESD belt

Belt speed

14 m/min.

PCB edge support

3 mm

Components clearance

Top 30 mm, bottom 30 mm

Power supply

230 VAC/50 Hz/1 Ph

Power consumption

350 VA max.

PCB cycle time

± 12 seconds

* or specify

MACHINE SIZES - 500

NTM 920DTCT

Machine L x W x H (mm)

500 x 1750 x 1100

Weight (Kg)

250

PCB Length (mm)

50 - 460

PCB Width (mm)

50 - 250

Traversing distance

330 mm (max.)*

Fixed rail to front (A) (mm)

237

* or specify

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.