DESTACKER

A stack of bare PCB’s is placed above the ESD belt conveyor by the operator. By using separation cams one PCB is separated from the bottom of the stack and dropped onto the ESD belt conveyor.

STANDARD FEATURES - DESTACKER

- Conveyor width adjustment using sliding mechanism.

- Controlled by PLC.

- Thin PCB capability.

- By-pass mode selectable. (Refer to drawing A for limitations)**

- LED towerlight display for machine status.

- CE certified.

Technical drawing - DESTACKER

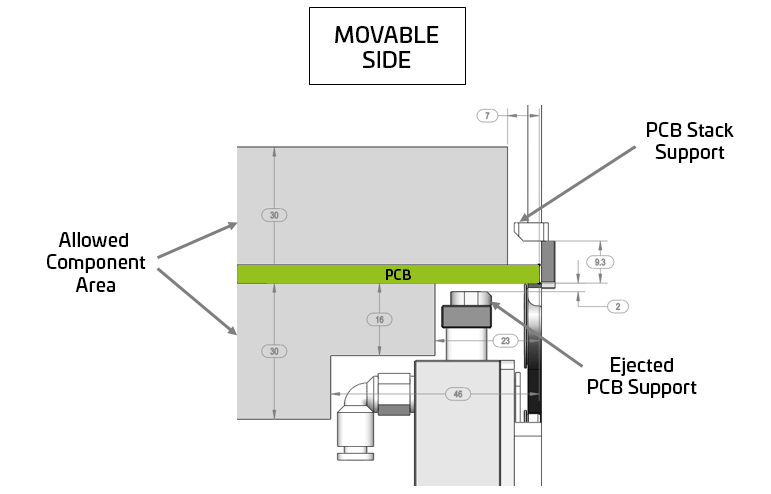

** Drawing - A

-

OPTIONS

- Alarm buzzer.

SPECIFICATIONS

Transfer height

950 mm ± 25 mm*

Colour

RAL 9002*

Flow direction

Left to Right*

Fixed rail

Front*

Machine interface

IPC-SMEMA-9851

Conveyor concept

ESD belt

Belt speed

14 m/min.

PCB edge support

3 mm

Component clearance (by-pass)

Top 30 mm, bottom 30 mm** (Refer to drawing A for limitations)**

Power supply

230 VAC/50 Hz/1 Ph

Power consumption

100 VA max.

Air supply

6 bar

Air consumption

5 ltr/min max.

PCB cycle time

± 5 seconds

PCB thickness

0.6 mm - 4 mm

PCB stock capacity

200 mm (max. 20 kg)

PCB weight

2,5 kg (max)

* or specify

MACHINE SIZES

NTE 0220DSL

Machine L x W x H (mm)

500 x 810 x 1185

Weight (Kg)

150

PCB Length (mm)

80 - 460

PCB Width (mm)

70 - 460

Fixed rail to front (A) (mm)

180

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.