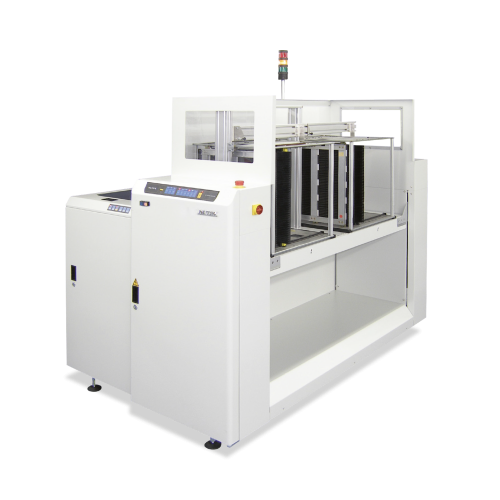

Ergonomic Multi Magazine Line Unloader

The Ergonomic Multi Magazine Line Unloader has a capacity of 7 magazines, providing 2 magazine conveyors placed side by side for convenient magazine exchange at ergonomic height, 1 for full magazines, 1 for empty magazines. 1 Magazine is on the servo and pneumatic driven shuttle conveyor. The upstream pusher conveyor pushes the PCB completely in the magazine. Magazines are automatically exchanged over. The 7” full colour touchscreen display allows easy operation on multiple user levels.

STANDARD FEATURES - Ergonomic Multi Magazine Line Unloader

- Servo driven lifter movement (vertical).

- Pneumatic driven shuttle movement (horizontal).

- 7” full colour touchscreen display.

- Advanced graphic Human Machine Interface (HMI).

- Multi level user acces control.

- In,- & Output diagnostics on touchscreen display.

- Flexible pitch settings.

- 2000 product recipes storage.

- 10 magazine recipes storage.

- Magazine loading ‘top to bottom’ or ‘bottom to top’.

- Tailor made to the magazine of your choice.

- Automatic magazine alignment by upper and lower pneumatic clamping.

- High throughput with short magazine change over time.

- Ethernet connection for network interface.

- LED towerlight display for machine status.

- CE Certified.

Technical drawing - Ergonomic Multi Magazine Line Unloader

OPTIONS

- IPC-HERMES-9852 communication.

- Automatic product change-over by Nutek leader - follower software.

- Line Control Software ready.

- Remotely accessible PLC.

- Increased magazine capacity.

- Reduced magazine capacity

- Width adjustable magazine conveyors to handle other magazine width.

- AGV/AIV prepared

- Alarm buzzer.

- Other options available on request

SPECIFICATIONS

Transfer height

950 mm ± 25 mm*

Colour

RAL 9002*

Flow direction

Left to right*

Fixed rail

Front*

Machine interface

IPC-SMEMA-9851*

Components clearance

Top 30 mm, bottom 30 mm

Power supply

230 VAC/50 Hz/1 Ph

Power consumption

740 VA max (including separate pusher conveyor)

Air supply

6 bar

Air consumption

20 ltr/min max (including separate pusher conveyor)

PCB unloading time

± 6 seconds

Magazine change over time

± 24 seconds (bottom to top sequence)

Pitch control

Flexible pitch settings

PCB thickness

0,4 - 4 mm

PCB weight

2,5 Kg (max)

Maximum magazine weight

50 Kg (each)

* or specify

Pusher conveyor

To be ordered separately

MACHINE SIZES - M

NTA 115UM

Machine L x W x H (mm)

1800 x 1540 x 1700

Weight (Kg)

400

PCB Length (mm)

80 - 330

PCB Width (mm)

70 - 250

Magazine dimensions (mm)

360 x 320 x 570

Fixed rail to front dim. X (mm)

460

Towerlight height Z (mm)

2000

*Depending on specifications

MACHINE SIZES - XL

NTA 115UXL

Machine L x W x H (mm)

2530 x 2165 x 1700

Weight (Kg)

580

PCB Length (mm)

80 - 460*

PCB Width (mm)

70 - 460*

Magazine dimensions (mm)

535 x 530 x 570*

Fixed rail to front dim. X (mm)

460

Towerlight height Z (mm)

2000

* Depending on specifications

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.

.png)