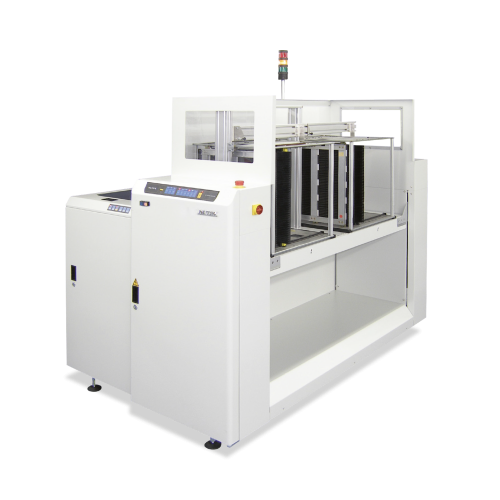

PUSHER CONVEYOR

The Pusher Conveyor is used in combination with any multi magazine line unloader and guarantees that PCB’s are completely pushed into the magazine.

STANDARD FEATURES - PUSHER CONVEYOR

> Controlled by multi magazine line unloader.

> Conveyor width adjustment using hand crank.

> Manual adjustable pusher position.

> Pneumatic stopper at inlet to control PCB flow from upstream oven.

> Regulated pressure on pneumatic pusher.

> CE certified.

Technical drawing - PUSHER CONVEYOR

OPTIONS

- Electrical conveyor width adjustment.

- Automatic conveyor width adjustment

- Pusher moves at ratio 1:2 to conveyor width

- Other options available on request

SPECIFICATIONS

Transfer height

950 mm ± 25 mm*

Colour

RAL 9002*

Flow direction

Left to right*

Fixed rail

Front*

Conveyor concept

ESD belt

Belt speed

14 m/min.

PCB edge support

3 mm

Machine interface

Controlled by unloader

Components clearance

Top 30 mm, bottom 30 mm

Power supply

Controlled by unloader

Power consumption

Controlled by unloader

Air supply

Controlled by unloader

Air consumption

Controlled by unloader

PCB cycle time

± 6 seconds

* or specify

MACHINE SIZES - M

NTM 110PM

Machine L x W x H (mm)

755 x 500 x 1100

Weight (Kg)

70

PCB Length (mm)

80 - 330

PCB Width (mm)

70 - 250

Fixed rail to front (A) (mm)

156

MACHINE SIZES - L

NTM 110PL

Machine L x W x H (mm)

950 x 660 x 1100

Weight (Kg)

85

PCB Length (mm)

80 - 460

PCB Width (mm)

70 - 407

Fixed rail to front (A) (mm)

156

MACHINE SIZES - XL

NTM 110PXL

Machine L x W x H (mm)

950 x 720 x 1100

Weight (Kg)

100

PCB Length (mm)

80 - 460*

PCB Width (mm)

70 - 460*

Fixed rail to front (A) (mm)

156

* or specify

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.

.png)