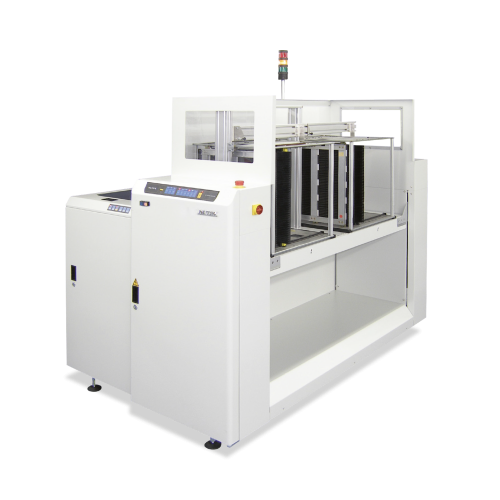

Multi magazine line unloader L-type

The Multi Magazine Line Unloader L-Type has a capacity of 6 magazines, 2 empty magazines are placed on the upper magazine conveyor. The lower magazine conveyor has a capacity for 3 full magazines. 1 Magazine is on the servo driven lifter. the upstream pusher conveyor pushes the PCB completely in the magazine. After a magazine is filled the magazine is automatically exchanged. This unloader has a reduced length as the magazine conveyors are positioned at a 90° angle. The 7” full colour touchscreen display allows easy operation on multiple user levels.

STANDARD FEATURES - Multi magazine line unloader L-type

- Servo driven lifter platform.

- 7” full colour touchscreen display.

- Advanced graphic Human Machine Interface (HMI).

- Multi level user acces control.

- In,- & Output diagnostics on touchscreen display.

- Flexible pitch settings.

- 2000 product recipes storage.

- 10 magazine recipes storage.

- Magazine unloading ‘top to bottom’ or ‘bottom to top’.

- Tailor made to the magazine of your choice.

- Automatic magazine alignment by upper and lower pneumatic clamping.

- High throughput with short magazine change over time.

- Ethernet connection for network interface.

- LED towerlight display for machine status.

- CE Certified.

Technical drawing - Multi magazine line unloader L-type

OPTIONS

- IPC-HERMES-9852 communication.

- Automatic product change-over by Nutek leader - follower software.

- Line Control Software ready.

- Automatic pusher positioning.

- Remotely accessible PLC.

- Safety shutter at outlet.

- Increased magazine capacity.

- Reduced magazine capacity

- Width adjustable magazine conveyors to handle other magazine width.

- Frontside magazine loading

- Alarm buzzer.

- Other options available on request

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.

.png)