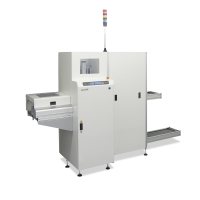

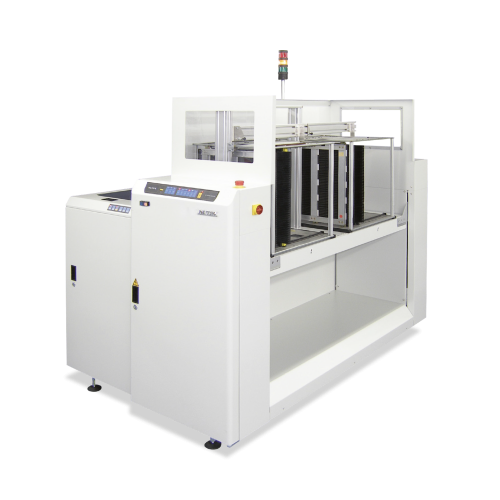

MULTI MAGAZINE LINE UNLOADER

The Multi Magazine Line Unloader provides automatic magazine change-over for continous line unloading. PCB’s are collected by the cantilevered pusher conveyor and pushed into the magazine. Full magazines are taken off at an ergonomic low level.

STANDARD FEATURES - MULTI MAGAZINE LINE UNLOADER

- Automatic magazine change-over.

- Automatic magazine alignment by upper and lower pneumatic clamping.

- Conveyor width adjustment using hand crank.

- Manual adjustable pusher position.

- Hinged top cover on pusher conveyor.

- Controlled by PLC.

- Tailor made to the magazine of your choice.

- Threshold signal to protect PCB’s in upstream oven.

- LED towerlight display for machine status.

- Selectable pitch settings.

- CE certified.

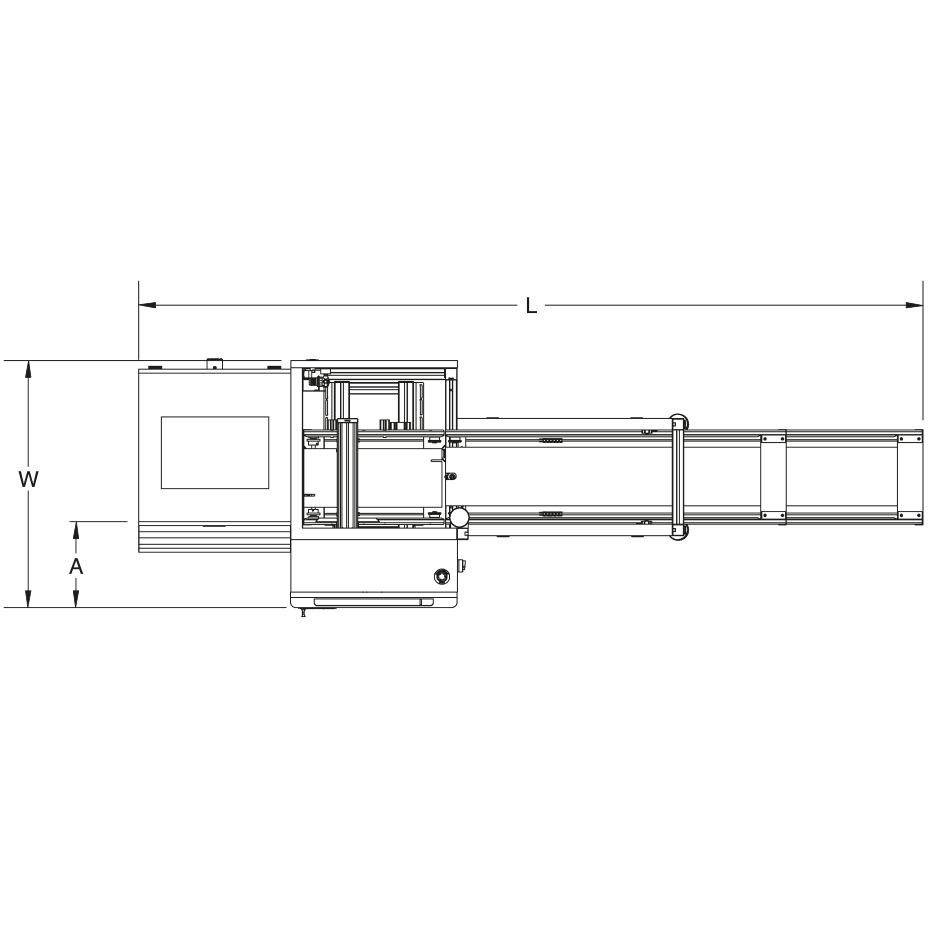

Technical drawing - MULTI MAGAZINE LINE UNLOADER

OPTIONS

- Pneumatic stopper at inlet to control PCB flow from upstream reflow oven

- Cooling fans on pusher conveyor

- Width adjustable magazine conveyors

- Additional magazine capacity

- Shorter magazine change-over (± 22 sec).

- Alarm buzzer.

- Reduced magazine capacity

- Safety shutter at inlet.

- Two selectable pitch slot sequences

- Unloading sequence top to bottom

- Alternative pitch selection 10-100 mm

- Additional cam plate

- Variable speed per segment

- Roller bearing support

- Pusher movement ratio 1:2

SPECIFICATIONS

Transfer height

950 mm ± 25 mm*

Colour

RAL 9002*

Flow direction

Left to right*

Fixed rail

Front*

Machine interface

IPC-SMEMA-9851

Conveyor concept

ESD belt

Belt speed

14 m/min

PCB edge support

3 mm

Components clearance

Top 30 mm, bottom 30 mm (depends on pitch)

Power supply

230 VAC/50Hz/1 Ph

Power consumption

600 VA max.

Air supply

6 bar

Air consumption

10 ltr/min max.

PCB unloading time

± 6 seconds

Magazine change-over time

± 40 seconds

Pitch control

1-4, 10 mm pitch

Max. total magazine weight

50 kg each

PCB weight

2,5 kg (max)

PCB thickness

0,8 - 4 mm

* or specify

Number of magazines

1

Magazine on the lifter platform.

2

Empty magazines on the upper magazine conveyor.

3

Full magazines on the lower magazine conveyor.

MACHINE SIZES

NTE 0110UL

Machine L x W x H (mm)

3075 x 975 x 1700

Weight (Kg)

310

PCB Length (mm)

80 - 460

PCB Width (mm)

70 - 460

Max. magazine dimens. (mm)

535 x 530 x 570

Fixed rail to front (A) (mm)

385

Interested in this product?

Download

Fill in the form to receive the datasheet in your mailbox, or create a Nutek account for unlimited download access. For any additional questions or remarks, please let us know and we'll get in touch.

.png)